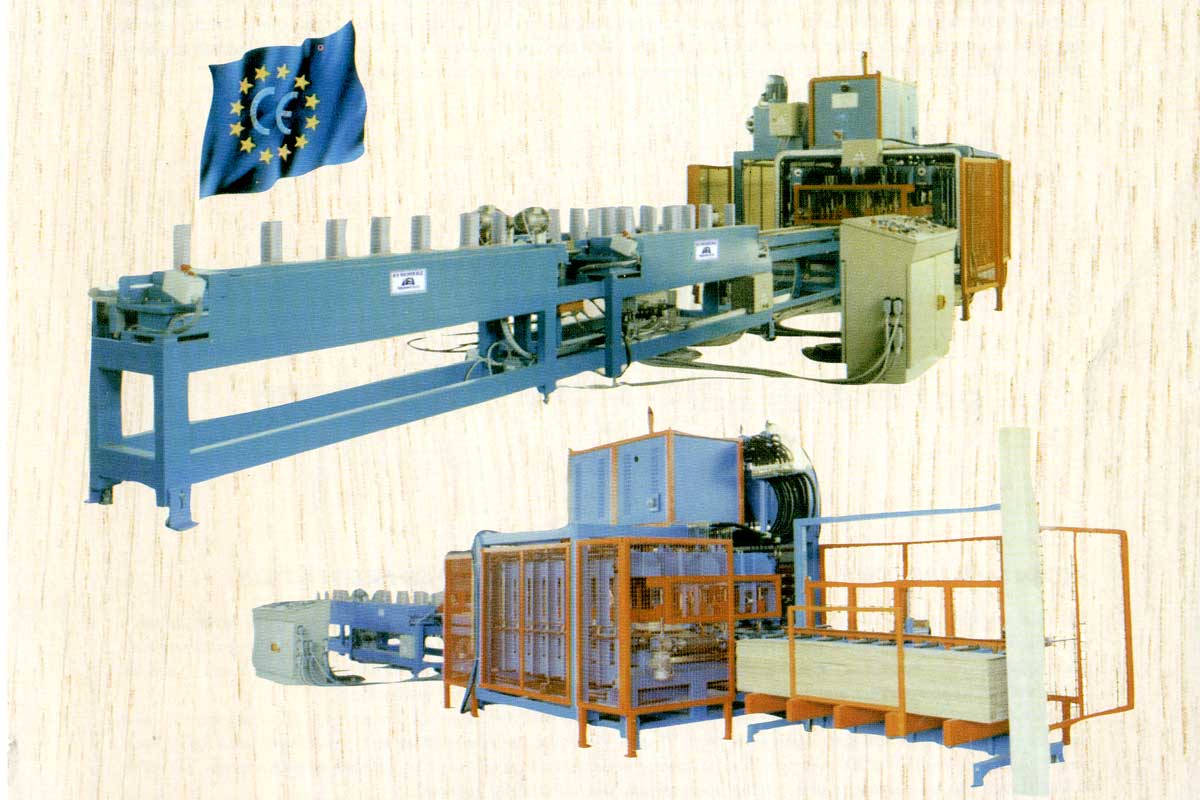

AUTOMATIC PRESSING LINES PARQUET UPPER LAYER PRODUCTION

Mod. EISNP 2200/3 – 2200/4 – 2200/5 HF

The line performs the composition, automatic gluing and stacking of panels for the upper layer of the parquet, mainly it is composed of three automatic slat loaders with nine containment tanks that can be adjusted according to the size of the slats and the desired composition, from a motorized roller glue spreading system, from a precomposition bench, from a double press compartment, from an automatic unloader – stacker

and from a dedicated high frequency generator.

PDF DOWNLOAD

The standard line involves the creation of parquet with three rows of boards, whose dimensions are 3.5 to 4 mm thick. length from 250 to 800mm. and width from 69 to 71mm, to achieve the composition in question with a maximum width of mm. 213 and maximum length of mm. 2200 with a production rate of 1 panel every 14 seconds (about 700 square meters in 8 hours) with the help of one operator for loading and one for checking.

These dimensions have been dictated by the current production standard but are not binding as it is possible to create lines with dimensions on request. In this particular case the high frequency allows in a very short time (about 6 seconds) the perfect polymerization of the glue, thus eliminating the stabilization times, necessary with the use of traditional gluing systems, very deleterious in this particular type of gluing (wood very thin and very hard which if not perfectly glued tends to reopen) and furthermore its use has been extensively tested even on particularly oily wood which is the recurring problem of traditional systems.

Contact us

Fill out the form below.

Ask any question or request a free quote

Call

+39 335 64 44 610

Contacts

Fill in and send this form.

Fields marked with an asterisk "*" are required for future contact.

Address

Via A. Modigliani 19b

10036 Settimo Torinese (TO)